Hiab Cranes

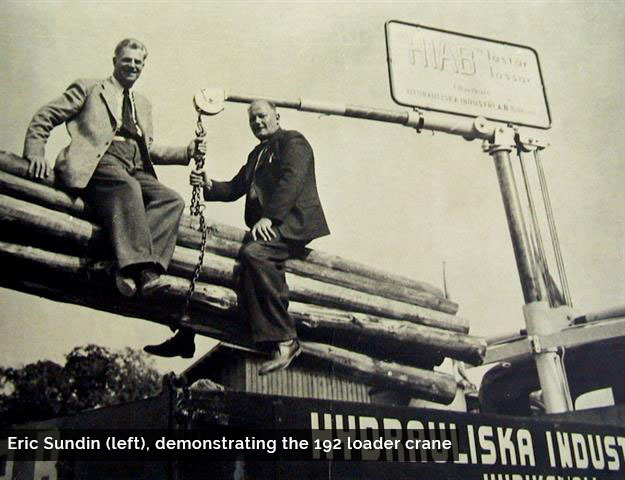

Hydrauliska Industri AB, HIAB, was established in 1944 by Eric Sundin of Hudiksvall, Sweden. Sundin created a hydraulic crane to move the heavy wood he used for his ski manufacturing company, an invention that gave us the revolutionized load handling we have today. The company’s first model, HIAB 192, used the truck’s own engine as power source,  creating the HIAB Method still used daily across the globe. Hydrauliska Industri AB is one of the leading manufacturers of on-road load handling equipment and continues the vision – “to unlock the full potential of load handling as a major contributor to industrial productivity.” Today, the company has around 2700 professionals working to provide high-performance product and service, with sales and service networks in over 100 countries.

creating the HIAB Method still used daily across the globe. Hydrauliska Industri AB is one of the leading manufacturers of on-road load handling equipment and continues the vision – “to unlock the full potential of load handling as a major contributor to industrial productivity.” Today, the company has around 2700 professionals working to provide high-performance product and service, with sales and service networks in over 100 countries.

An elephant logo emblazons the HIAB headline and is a reminder of both the company’s history and their ongoing strength. The “Elefant” loader crane, presented by the company in 1956, led to today’s “knuckleboom” crane standard. In 1985, Partek Corporation, one of the leading industrial companies of Finland, acquired HIAB as part of their expansion into the engineering domain. Innovation, service, and performance throughout the years has led them to be a part of many other leading load-handling businesses. HIAB acquired JONSERED Forestry in 1979, around the same time Partek bought Multilift group. KONE Corporation acquired Partek in 2002, becoming Cargotec Corporation. Hiab has been the name for the whole load handling business in Cargotec since 2004.

An elephant logo emblazons the HIAB headline and is a reminder of both the company’s history and their ongoing strength. The “Elefant” loader crane, presented by the company in 1956, led to today’s “knuckleboom” crane standard. In 1985, Partek Corporation, one of the leading industrial companies of Finland, acquired HIAB as part of their expansion into the engineering domain. Innovation, service, and performance throughout the years has led them to be a part of many other leading load-handling businesses. HIAB acquired JONSERED Forestry in 1979, around the same time Partek bought Multilift group. KONE Corporation acquired Partek in 2002, becoming Cargotec Corporation. Hiab has been the name for the whole load handling business in Cargotec since 2004.

HIAB’s mission – to deliver load handling products that are reliable and efficient, so customers can run their businesses with sustainable profitability, pride and peace of mind – is evidenced in their ability to meet the needs of national, regional, and local enterprises that make up the their customer base and cover business areas such as construction, infrastructure, distribution, forestry, landscaping and agriculture, warehousing, waste and recycling, and defense. The product range now includes: HIAB loader cranes, JONSERED recycling and forestry cranes, LOGLIFT forestry cranes, MOFFETT truck mounted forklifts and MULTILIFT demountables, as well as DEL, WALTCO and ZEPRO tail lift.

HIAB’s mission – to deliver load handling products that are reliable and efficient, so customers can run their businesses with sustainable profitability, pride and peace of mind – is evidenced in their ability to meet the needs of national, regional, and local enterprises that make up the their customer base and cover business areas such as construction, infrastructure, distribution, forestry, landscaping and agriculture, warehousing, waste and recycling, and defense. The product range now includes: HIAB loader cranes, JONSERED recycling and forestry cranes, LOGLIFT forestry cranes, MOFFETT truck mounted forklifts and MULTILIFT demountables, as well as DEL, WALTCO and ZEPRO tail lift.

HIAB Crane Models

“Amongst our most popular knuckle boom cranes,” says Lotta Clausen, Vice President Communications with HIAB,

“you find the XS 144 HiDuo and XS 166 HiDuo.” Both of these are universal cranes that fit a wide range of

trucks and are equipped with a remote control. “Being able to choose between various steering systems, HIAB allows our customers to invest on the right level according to his/her business,” continues Ms. Clausen.

The company has a wide range of knuckle boom crane models with capacities beginning at 0.5 ton all the way up to 90 ton, and with outreaches spreading from 4.2 to 38 meters. With consistent innovation comes many models, and to navigate your way to find the right fit for you, the name is a significant indicator. HIAB X, is the evolution from XS, and simply indicates the crane model is fitted with a foldable boom system. CLX models indicate advanced technology (X) on the predecessor, the Classic (CL) series. The number in the model name gives you an idea of the loader crane’s capacity.

You may choose from HiDuo or HiPro control systems, and this will be indicated in the model name as well, especially when purchasing a previously used crane. Both control systems use SPACE-Intelligence Systems that include Over Load Protection (OLP). In addition to Automatic Duty Control (ADC) and Automatic Speed Control (ASC) functions featured in SPACE 4000, SPACE 5000 also features Pump Flow Distribution (PFD).